Following the recommended settings when applying heat transfer vinyl (HTV) is essential to achieve the best possible results and ensure the finished product is durable and long-lasting. These settings consider several factors, such as the type of fabric, the temperature of the heat press, the amount of pressure, and the length of time needed to apply the HTV.

Using incorrect settings can result in HTV that doesn’t adhere properly to the fabric, peels over time, or cracks during washing. This can lead to wasted material, lost time, and dissatisfied customers. Moreover, incorrect settings may damage the fabric, causing it to shrink, burn, or discolor, further increasing the risk of a poor-quality product.

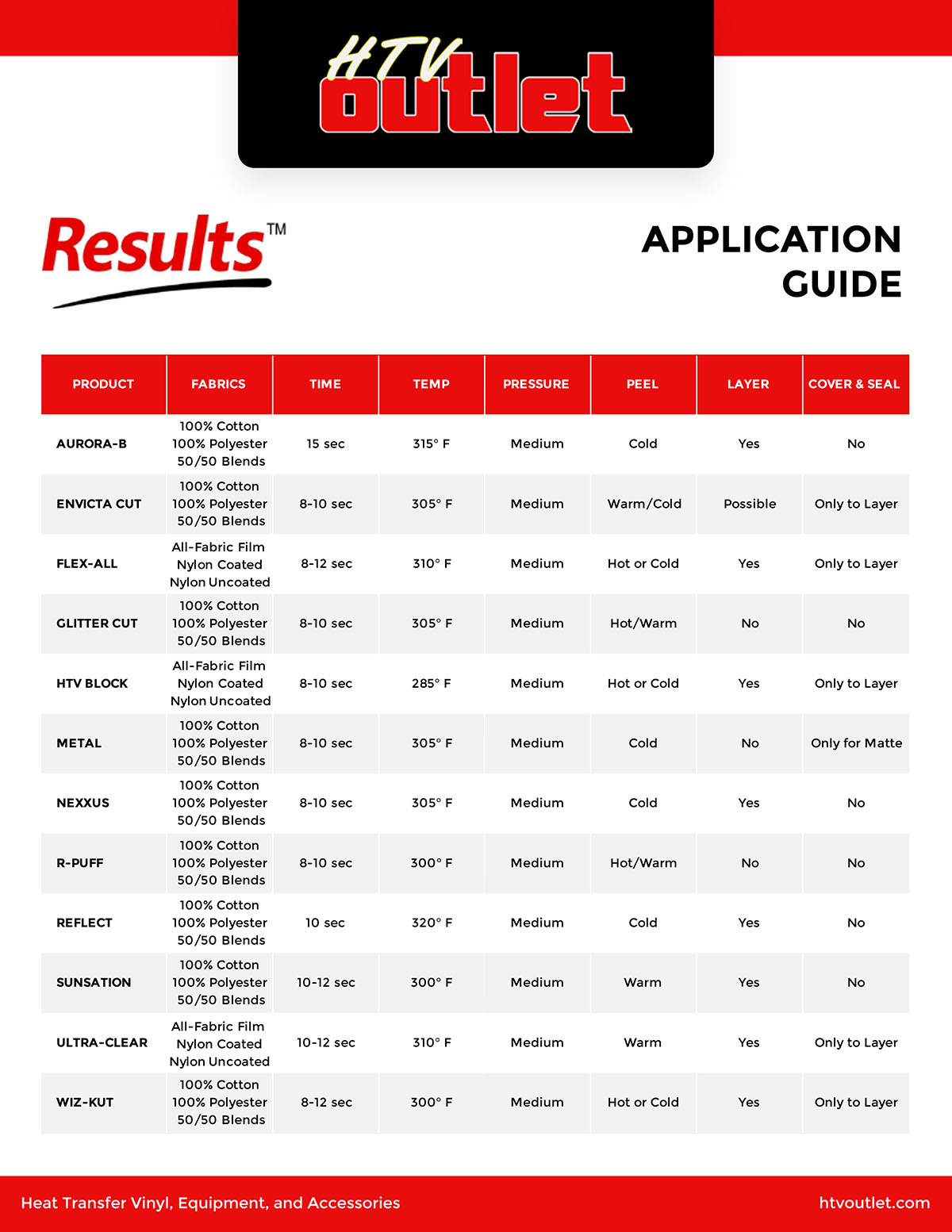

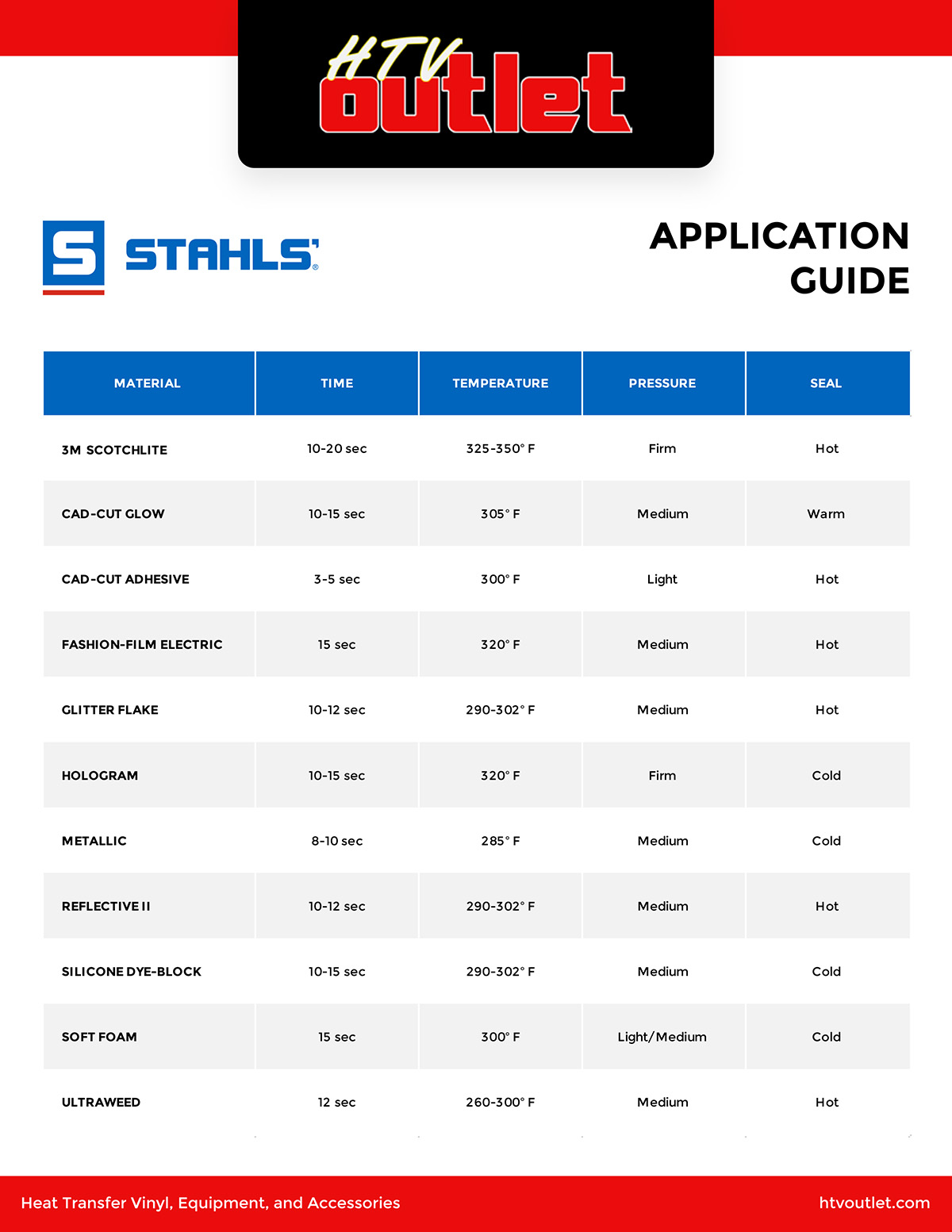

We created the following guides to help ensure you produce high-quality, durable, and long-lasting heat transfer vinyl designs.

Our guides are designed to give you the tools and knowledge to create stunning designs that are durable, long-lasting, and unforgettable. Read the others and take your heat transfer vinyl projects to the next level.