When cutting heat transfer vinyl, it is crucial to follow the recommended settings to achieve the desired results and ensure the longevity of the finished product. These settings consider factors such as the type of vinyl being used, the blade depth, and the speed and pressure of the cutter. If these settings are not followed correctly, the vinyl may be cut poorly, too deeply, or not deeply enough, resulting in poor-quality designs that peel or crack over time.

Not only can using incorrect settings impact the quality of the final product, but it can also lead to wasted material and lost time. Having to redo a cutting job due to improper settings will result in additional expenses and delays, which can be frustrating for you and your customers.

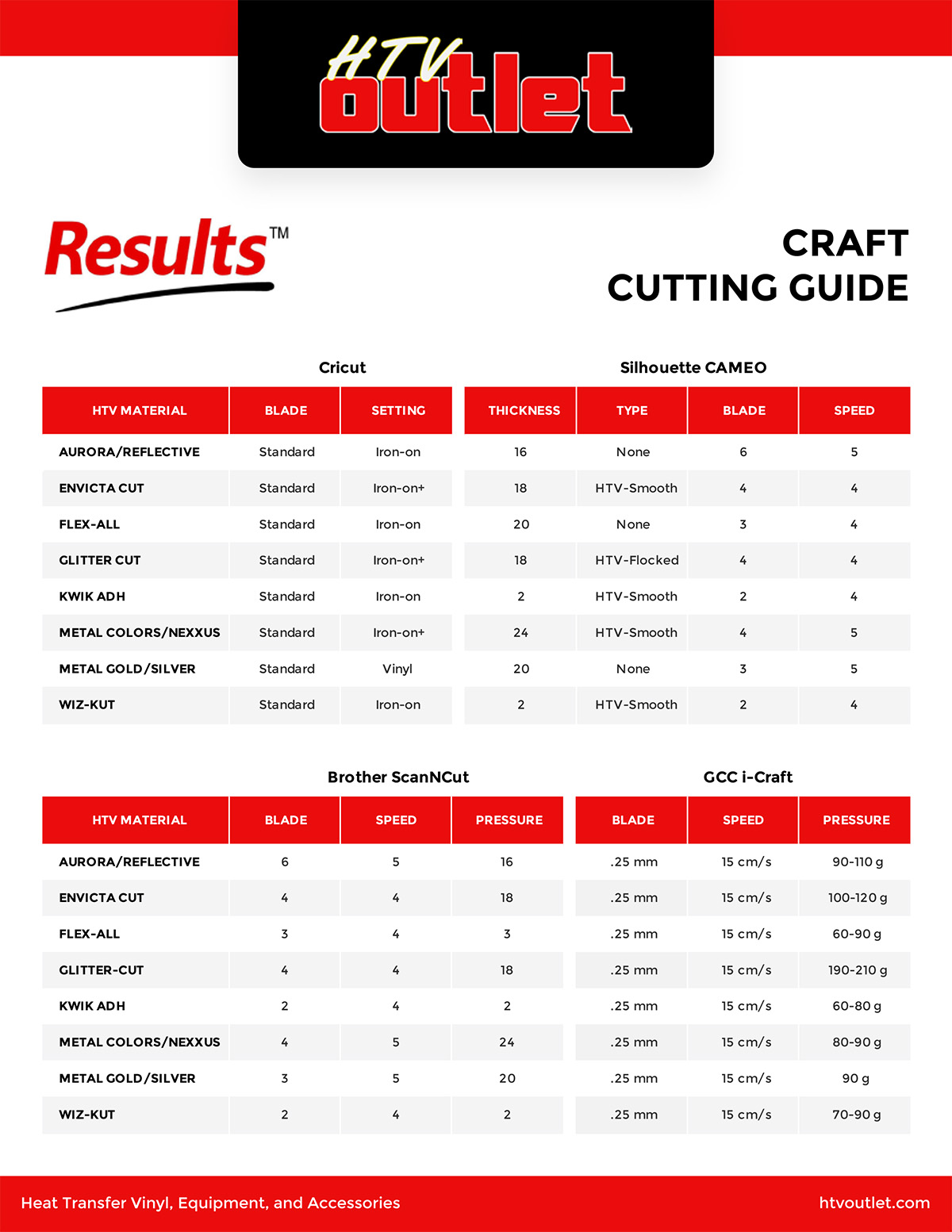

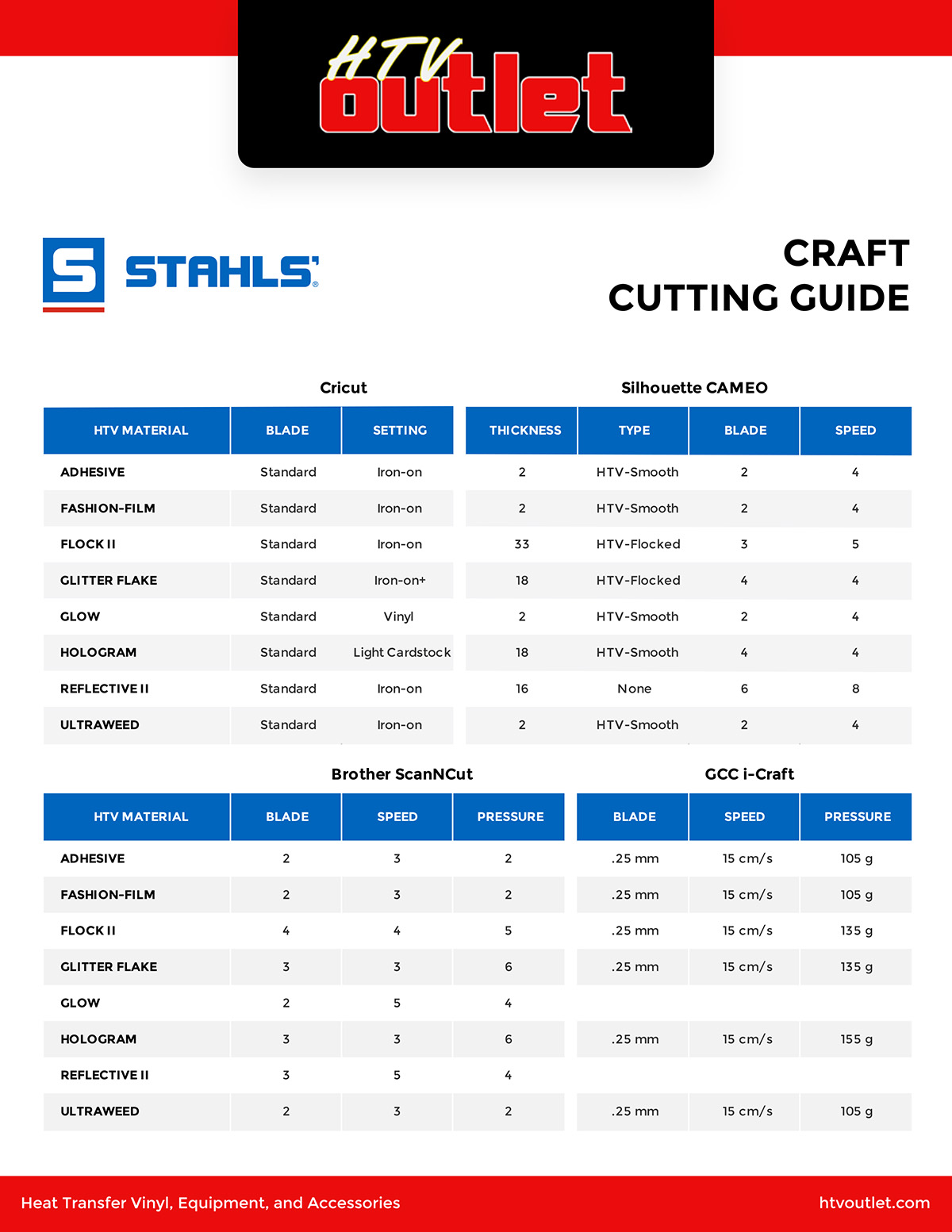

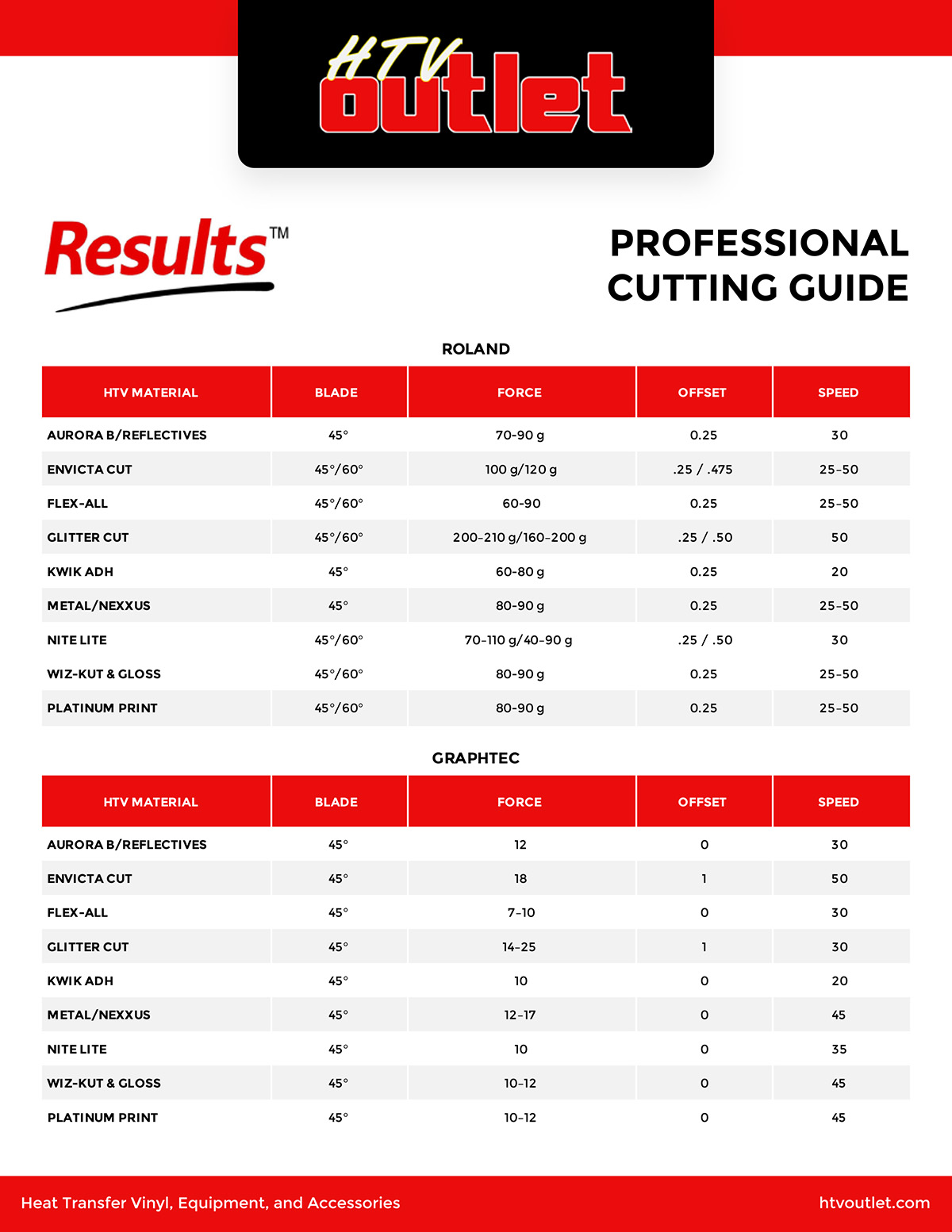

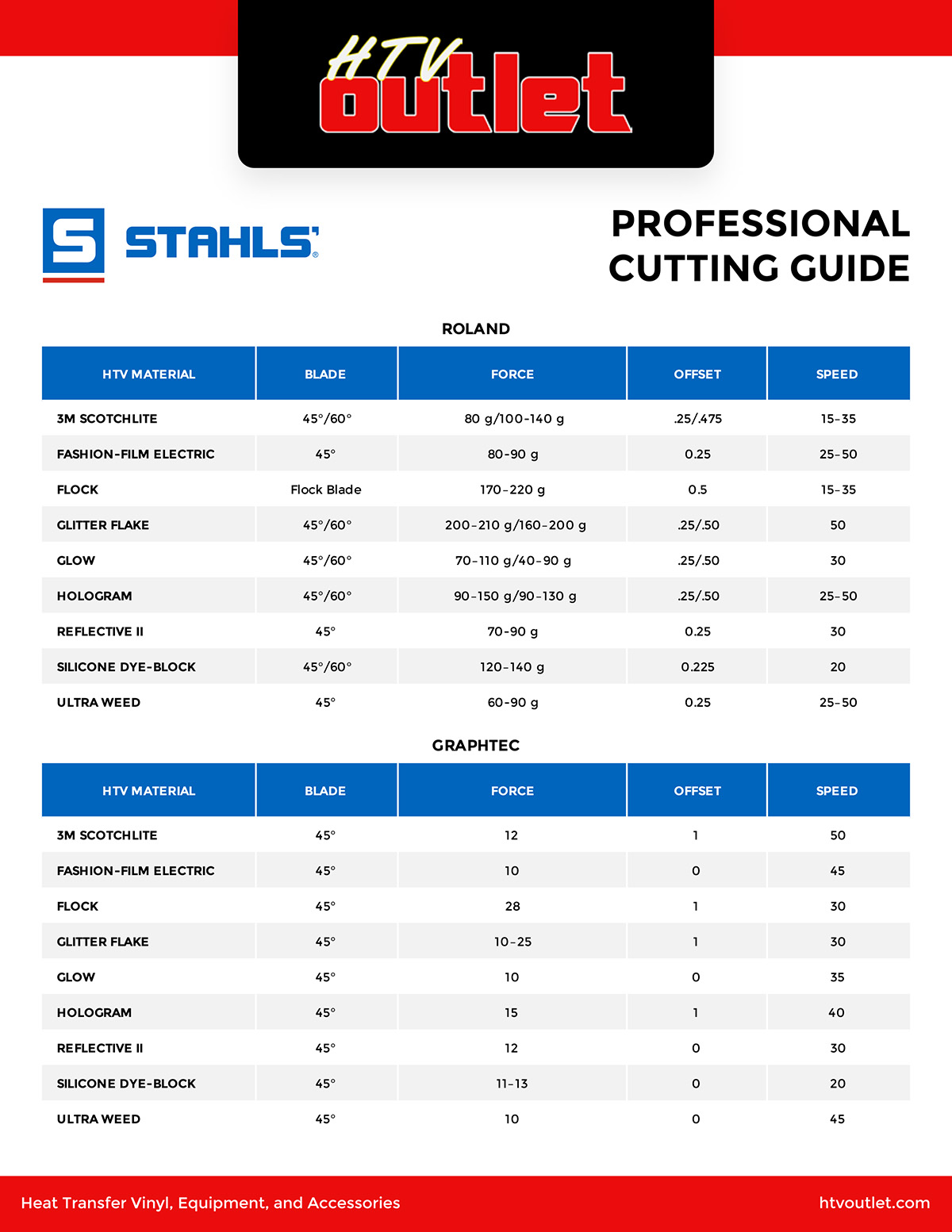

Use the following settings to ensure your heat transfer vinyl designs are high-quality, durable, and long-lasting.

Browse the rest of our guides to reach new heights with your heat transfer vinyl creations. From selecting suitable materials to mastering the cutting process and ensuring proper application, we cover everything you need to know to create stunning designs that stand the test of time.